Is the pull-out box structural design stable and durable?

Release Time : 2025-10-04

In modern packaging design, the balance between form and function is gaining increasing importance. Consumers not only focus on the product within the package, but also increasingly care about the experience and feeling during the unboxing process. As a packaging structure that combines aesthetics and practicality, the pull-out box, with its unique drawer-like opening, breaks away from the conventional flip-top or slide-top model, offering a refreshing interactive experience. However, novel designs lack solid structural support and struggle to survive in real-world use. Therefore, the stability and durability of a pull-out box's structure become a core criterion for evaluating its quality. It not only affects the integrity of the packaging during transportation and storage, but also directly impacts the user experience and initial impression of the brand.

The stability of a pull-out box is primarily reflected in the rationality of its overall structure. It typically consists of an outer box and an inner drawer. The outer box serves as a fixed outer shell, providing external protection and visual display; the inner drawer holds the contents and slides out of the outer box. The connection between these two parts is not simply nested, but rather a result of carefully calculated dimensional coordination and structural reinforcement. The outer box's walls are typically constructed of high-weight cardboard or multi-layer composite materials, ensuring a rigid, sturdy structure that resists collapse. The inner drawer's edges are reinforced to prevent warping or cracking during repeated opening and closing. This synergistic design ensures the box maintains its shape even under certain external forces, preventing deformation from squeezing or impact.

When it comes to durability, the key to a pull-out box lies in the stability and durability of its sliding mechanism. High-quality pull-out boxes are designed to balance friction and load-bearing capacity, ensuring smooth opening and closing while preventing the drawer from accidentally sliding out due to excessive looseness. Some high-end designs incorporate guides, sliders, or cushioning pads on the contact surfaces to further enhance sliding precision and longevity. Even after repeated opening and closing, the structure remains tightly fitted, preventing loosening, shaking, or sticking. This durability, which withstands repeated use, not only enhances the packaging's practicality but also demonstrates the brand's commitment to quality.

Furthermore, a stable structure ensures reliable protection for the contents. During logistics and transportation, packaging inevitably experiences bumps, stacking, and vibration. Pull-out boxes utilize strategic internal compartments, custom-designed inner supports, or cushioning materials to securely secure products within their inner drawers, preventing bumps and damage caused by movement. The enclosed outer box also effectively blocks dust, moisture, and external contaminants, ensuring the product arrives in optimal condition. This comprehensive protection mechanism makes the pull-out box not only a display item but also a reliable transport vehicle.

From a user experience perspective, structural stability directly determines the integrity of the unboxing experience. Loose, deformed, or difficult-to-open packaging can instantly undermine expectations and even cast doubt on the product's quality. On the other hand, a solidly constructed, smoothly sliding pull-out box conveys a sense of meticulous design and quality from the moment it's opened. With a gentle push of the finger, the inner drawer slides out smoothly, revealing its contents. The entire process feels like a carefully choreographed presentation, both solemn and surprising. This smooth and reliable interaction strengthens the emotional connection between the user and the brand.

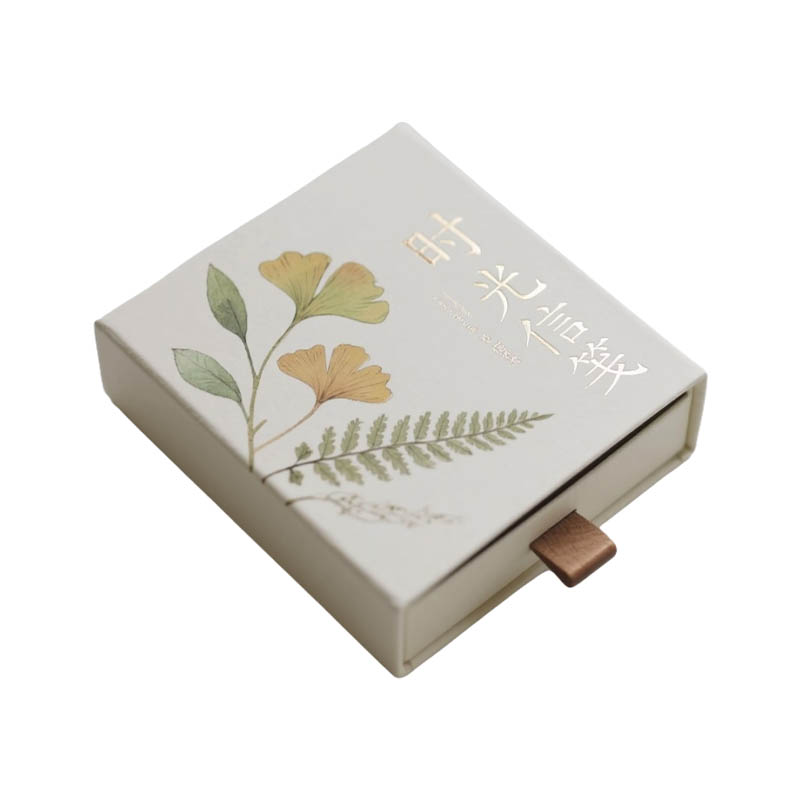

At the same time, the stable structure also provides greater design flexibility for brands. The outer box's surface can be treated with high-end finishes like hot stamping, embossing, UV treatments, and hollowing to enhance visual depth. The inner drawer's opening process can be enhanced with layered displays, lighting effects, or hidden information to enhance narrative. These creative expressions rely on a stable structure; otherwise, even the most exquisite design will be compromised by structural flaws.

In summary, the pull-out box's structural design not only pursues formal innovation but also prioritizes inherent stability and durability. Its robust materials, precise craftsmanship, and user-friendly details ensure every opening experience is a memorable one. Choosing this type of packaging not only enhances the product's appearance but also represents a long-term investment in brand image and customer trust.

The stability of a pull-out box is primarily reflected in the rationality of its overall structure. It typically consists of an outer box and an inner drawer. The outer box serves as a fixed outer shell, providing external protection and visual display; the inner drawer holds the contents and slides out of the outer box. The connection between these two parts is not simply nested, but rather a result of carefully calculated dimensional coordination and structural reinforcement. The outer box's walls are typically constructed of high-weight cardboard or multi-layer composite materials, ensuring a rigid, sturdy structure that resists collapse. The inner drawer's edges are reinforced to prevent warping or cracking during repeated opening and closing. This synergistic design ensures the box maintains its shape even under certain external forces, preventing deformation from squeezing or impact.

When it comes to durability, the key to a pull-out box lies in the stability and durability of its sliding mechanism. High-quality pull-out boxes are designed to balance friction and load-bearing capacity, ensuring smooth opening and closing while preventing the drawer from accidentally sliding out due to excessive looseness. Some high-end designs incorporate guides, sliders, or cushioning pads on the contact surfaces to further enhance sliding precision and longevity. Even after repeated opening and closing, the structure remains tightly fitted, preventing loosening, shaking, or sticking. This durability, which withstands repeated use, not only enhances the packaging's practicality but also demonstrates the brand's commitment to quality.

Furthermore, a stable structure ensures reliable protection for the contents. During logistics and transportation, packaging inevitably experiences bumps, stacking, and vibration. Pull-out boxes utilize strategic internal compartments, custom-designed inner supports, or cushioning materials to securely secure products within their inner drawers, preventing bumps and damage caused by movement. The enclosed outer box also effectively blocks dust, moisture, and external contaminants, ensuring the product arrives in optimal condition. This comprehensive protection mechanism makes the pull-out box not only a display item but also a reliable transport vehicle.

From a user experience perspective, structural stability directly determines the integrity of the unboxing experience. Loose, deformed, or difficult-to-open packaging can instantly undermine expectations and even cast doubt on the product's quality. On the other hand, a solidly constructed, smoothly sliding pull-out box conveys a sense of meticulous design and quality from the moment it's opened. With a gentle push of the finger, the inner drawer slides out smoothly, revealing its contents. The entire process feels like a carefully choreographed presentation, both solemn and surprising. This smooth and reliable interaction strengthens the emotional connection between the user and the brand.

At the same time, the stable structure also provides greater design flexibility for brands. The outer box's surface can be treated with high-end finishes like hot stamping, embossing, UV treatments, and hollowing to enhance visual depth. The inner drawer's opening process can be enhanced with layered displays, lighting effects, or hidden information to enhance narrative. These creative expressions rely on a stable structure; otherwise, even the most exquisite design will be compromised by structural flaws.

In summary, the pull-out box's structural design not only pursues formal innovation but also prioritizes inherent stability and durability. Its robust materials, precise craftsmanship, and user-friendly details ensure every opening experience is a memorable one. Choosing this type of packaging not only enhances the product's appearance but also represents a long-term investment in brand image and customer trust.