How do boutique special-shaped boxes balance structural strength and ease of opening?

Release Time : 2025-10-16

Amidst consumer upgrades and increasingly fierce brand competition, packaging has evolved from a simple product container to a crucial vehicle for conveying brand value and enhancing user experience. Boutique special-shaped boxes, with their unconventional three-dimensional shapes, unique visual impact, and highly customizable presentation, have become the preferred packaging format for high-end gifts, luxury goods, digital products, and cultural and creative products. However, while these unique designs offer aesthetic breakthroughs, they also pose significant functional challenges. On the one hand, non-standard geometric structures can reduce pressure-bearing capacity and lead to collapse and deformation during transportation. On the other hand, complex folding methods can make it difficult for users to open the boxes smoothly, impacting the user experience. Achieving a perfect balance between structural strength and ease of opening is the core proposition of boutique special-shaped box design.

1. Scientific Structural Mechanics Design: Enhancing Stability Through Geometric Form

The structural strength of boutique special-shaped boxes stems not from material thickness but from their sophisticated geometric construction. Designers employ architectural principles such as "arch support," "triangular stability," and "honeycomb partitioning" to construct an invisible load-bearing skeleton within the box. For example, a polyhedral folding structure distributes external forces across multiple edges and corners; or reinforcing ribs and internal support panels are incorporated into the bottom to form a closed, compressive framework. For suspended display boxes, diagonal braces or curved sidewalls are often used for self-support, reducing weight while increasing overall rigidity. This "form-fortifying" design concept allows even thin cardboard to withstand stacking pressure, ensuring product safety during transportation and display.

2. Precise Die-Cutting and Creasing: Laying the Foundation for Forming

The strength and opening and closing performance of custom-shaped boxes are highly dependent on manufacturing precision. Modern digital die-cutting technology achieves a cutting tolerance of ±0.1mm, ensuring every edge and every latch is perfectly aligned. The depth, width, and placement of the creasing lines are precisely calculated to ensure smooth folding while avoiding structural weakening due to excessive depth or breakage due to excessive shallowness. Especially for curved surfaces or sharp corners, micro-serrated indentations or gradient indentation techniques are used to effectively prevent tearing of paper fibers and enhance the durability of the box. High-precision craftsmanship is the technical guarantee for the "sturdiness" of special-shaped boxes.

3. Synergistic Optimization of Materials and Structures

Boutique special-shaped boxes typically use heavyweight white cardboard, art paper, or composite paperboard, which combines stiffness with printability. For applications requiring higher strength, corrugated cardboard or PET sheets can be partially laminated as a support layer. Furthermore, pre-folding is used to pre-adapt the paper fibers to the folding angle, reducing springback and improving structural stability. Environmentally friendly hot-melt or water-based adhesives are used for bonding, ensuring a secure bond without spillage that could affect the appearance.

4. Integration of Function and Aesthetics

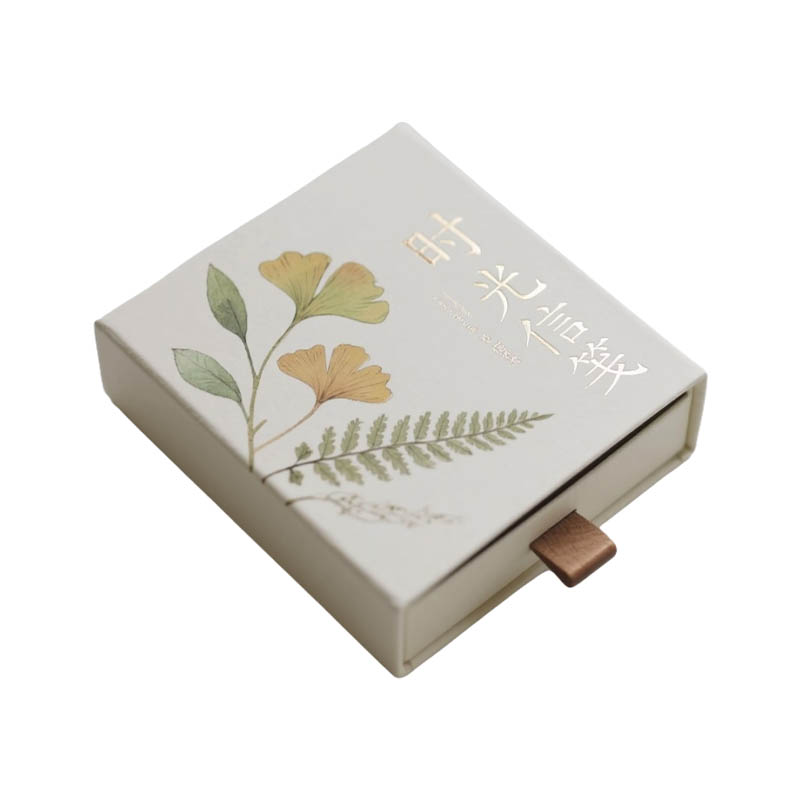

Excellent special-shaped box designs integrate strength and convenience into their overall aesthetics. For example, the opening mechanism is concealed within the pattern, the buckle is integrated into the decorative molding, and the drawer handles are made of fabric or metal in the same color as the box, creating a functional yet stylish look. Structure isn't just support; it's part of the narrative—every opening becomes a continuation of the brand story.

In summary, the boutique special-shaped boxes achieve the dual goals of structural strength and ease of opening through "scientific structural design, precision manufacturing, a user-friendly opening mechanism, and material synergy." More than just a protective case for the product, they offer a sensory experience that blends engineering expertise with artistic expression, redefining the functional boundaries and emotional value of high-end packaging.

1. Scientific Structural Mechanics Design: Enhancing Stability Through Geometric Form

The structural strength of boutique special-shaped boxes stems not from material thickness but from their sophisticated geometric construction. Designers employ architectural principles such as "arch support," "triangular stability," and "honeycomb partitioning" to construct an invisible load-bearing skeleton within the box. For example, a polyhedral folding structure distributes external forces across multiple edges and corners; or reinforcing ribs and internal support panels are incorporated into the bottom to form a closed, compressive framework. For suspended display boxes, diagonal braces or curved sidewalls are often used for self-support, reducing weight while increasing overall rigidity. This "form-fortifying" design concept allows even thin cardboard to withstand stacking pressure, ensuring product safety during transportation and display.

2. Precise Die-Cutting and Creasing: Laying the Foundation for Forming

The strength and opening and closing performance of custom-shaped boxes are highly dependent on manufacturing precision. Modern digital die-cutting technology achieves a cutting tolerance of ±0.1mm, ensuring every edge and every latch is perfectly aligned. The depth, width, and placement of the creasing lines are precisely calculated to ensure smooth folding while avoiding structural weakening due to excessive depth or breakage due to excessive shallowness. Especially for curved surfaces or sharp corners, micro-serrated indentations or gradient indentation techniques are used to effectively prevent tearing of paper fibers and enhance the durability of the box. High-precision craftsmanship is the technical guarantee for the "sturdiness" of special-shaped boxes.

3. Synergistic Optimization of Materials and Structures

Boutique special-shaped boxes typically use heavyweight white cardboard, art paper, or composite paperboard, which combines stiffness with printability. For applications requiring higher strength, corrugated cardboard or PET sheets can be partially laminated as a support layer. Furthermore, pre-folding is used to pre-adapt the paper fibers to the folding angle, reducing springback and improving structural stability. Environmentally friendly hot-melt or water-based adhesives are used for bonding, ensuring a secure bond without spillage that could affect the appearance.

4. Integration of Function and Aesthetics

Excellent special-shaped box designs integrate strength and convenience into their overall aesthetics. For example, the opening mechanism is concealed within the pattern, the buckle is integrated into the decorative molding, and the drawer handles are made of fabric or metal in the same color as the box, creating a functional yet stylish look. Structure isn't just support; it's part of the narrative—every opening becomes a continuation of the brand story.

In summary, the boutique special-shaped boxes achieve the dual goals of structural strength and ease of opening through "scientific structural design, precision manufacturing, a user-friendly opening mechanism, and material synergy." More than just a protective case for the product, they offer a sensory experience that blends engineering expertise with artistic expression, redefining the functional boundaries and emotional value of high-end packaging.