How does the printing process for pull-out boxes achieve high-precision pattern rendering?

Release Time : 2025-10-30

As a packaging format that combines practicality and design, achieving high-precision printing of pull-out boxes requires a collaborative approach across seven dimensions: material selection, equipment precision, process optimization, color management, detail processing, environmental control, and a comprehensive quality control system. This collaboration aims to ensure accurate pattern reproduction and enhanced visual quality.

Material selection is fundamental to the printing process. The outer layer of the pull-out box must balance flexibility and surface smoothness. For example, high-grammage coated paper or art paper can support complex patterns while enhancing ink adhesion through surface coatings. The inner grey board layer must maintain uniform thickness to prevent printing misalignment due to material deformation. Material compatibility is equally crucial; the matching degree between the laminating material and the ink directly impacts the final presentation.

Equipment precision is the core of ensuring pattern reproduction. Modern printing presses employ servo motor drives and closed-loop control systems, using encoders to provide real-time feedback on movement position, ensuring that the positioning error between the squeegee and the screen is controlled within the micrometer level during high-speed operation. The introduction of a visual positioning system further enhances accuracy. A high-resolution camera automatically identifies deviations between the substrate and the screen and dynamically adjusts during printing, effectively compensating for errors caused by equipment vibration or material deformation.

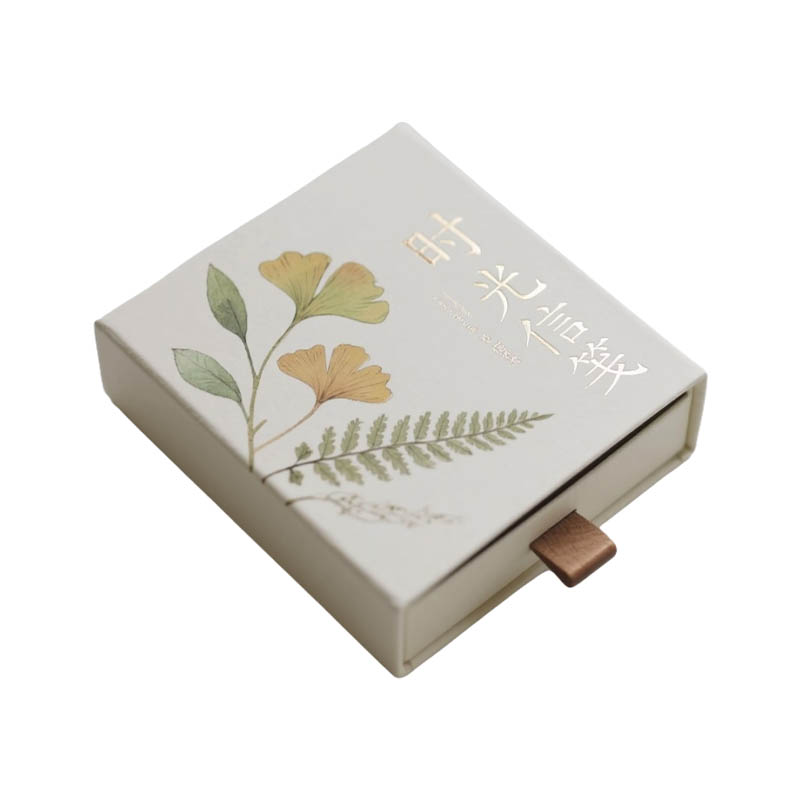

Process optimization requires adjustments tailored to the structural characteristics of the pull-out box. High-precision cutting tools are needed in the die-cutting process to ensure smooth edges on the pull-out tracks of the outer and inner boxes, preventing burrs from affecting printing alignment. Localized UV coating, by precisely controlling the UV irradiation area, can highlight the brand logo or key patterns, enhancing visual depth. Embossing and hot stamping processes need to be deeply integrated with the printed pattern; for example, overlaying metallic luster on embossed textures enhances both tactile and visual experience.

Color management is integrated throughout the entire printing process. A professional color management system collects ink color values using a spectrometer, generating ICC profiles consistent with brand standards to ensure color consistency across different batches. Digital color correction technology is used in the proofing stage to control the color difference between the design and the physical sample to a level imperceptible to the naked eye. For complex gradient patterns, color separation software is used to optimize dot distribution, avoiding highlights or loss of detail in shadows.

Attention to detail reflects the level of craftsmanship. Microgravure printing technology achieves precise line rendering down to 0.1 mm, suitable for decorative patterns on the edges of pull-out boxes. Cold foil stamping, using low-temperature transfer film materials, achieves seamless bonding of metallic textures to curved or irregularly shaped structures, overcoming the limitations of traditional hot foil stamping on material shape. These detailed processes create a dynamic visual effect as the box is pulled out.

Environmental control ensures stable printing quality. The production workshop maintains constant temperature and humidity conditions, with temperature fluctuations controlled within ±2℃ and humidity maintained at 55%±5%, avoiding misregistration caused by paper expansion due to moisture absorption or contraction during drying. An air purification system filters particles larger than 0.3 micrometers in diameter, preventing dust adhesion from affecting print clarity. Strict control of these environmental parameters provides a reliable foundation for high-precision printing.

A quality inspection system ensures that the final product meets standards. Automated optical inspection equipment scans the entire surface of each pull-out box, identifying printing defects larger than 0.05 mm, such as omissions, color differences, and scratches. Manual sampling inspection focuses on the smoothness of the pull-out function and structural stability to ensure that the pattern remains intact during repeated use. Through multi-level quality inspection processes, the product qualification rate has been significantly improved.