How to ensure a telescopic box doesn't deform or jam during repeated pushing and pulling?

Release Time : 2025-12-05

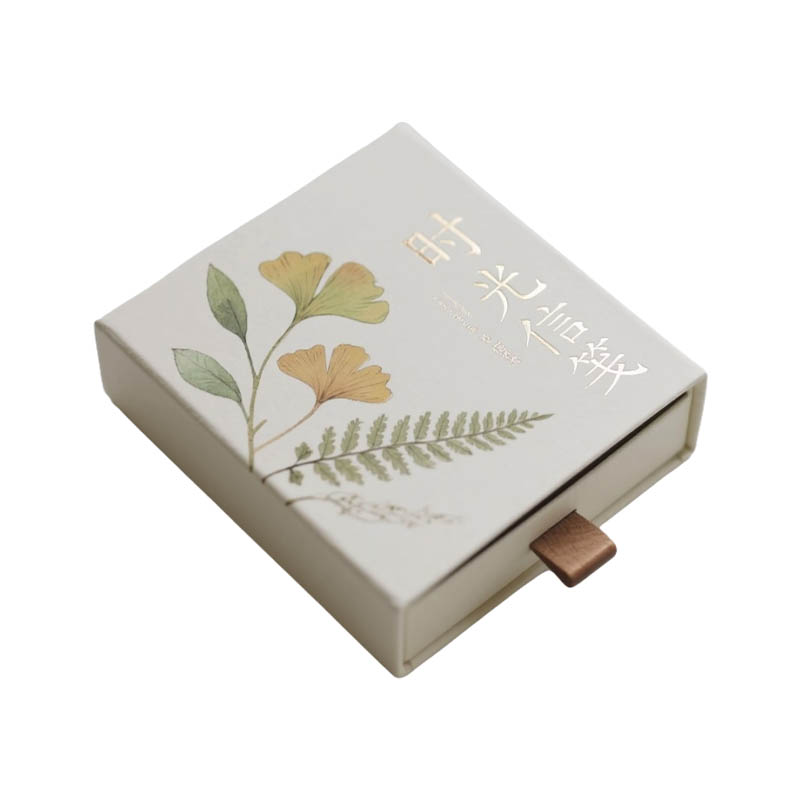

In the high-end packaging sector, telescopic boxes, with their elegant opening mechanism and refined structure, are widely used in cosmetics, jewelry, electronics, and gifts. Their core appeal lies in "smooth pushing and pulling, precise return to center, and a premium feel," all of which are based on a scientific balance between the cardboard's weight and stiffness. If the cardboard is too thin or lacks stiffness, the box is prone to bending and collapsing during use, leading to jamming or even failure to return to its original position; if it's too thick, it sacrifices the smooth sliding feel, appearing clumsy and rigid. Therefore, achieving a balance between flexibility and rigidity is key to telescopic box design.

First, the weight determines the basic thickness and strength reserve of the cardboard. High-weight cardboard is typically thicker, providing stronger resistance to compression and bending, suitable for carrying heavier contents or for applications requiring long-term use. However, in telescopic boxes, simply pursuing high grammage is not a good strategy—excessively thick cardboard increases friction between the inner and outer boxes, making pushing and pulling difficult, and even causing jamming due to accumulated tolerances. Therefore, designers need to select an appropriate grammage range based on the product's weight, usage frequency, and structural dimensions, ensuring the box doesn't deform under stress while allowing sufficient clearance for sliding.

Secondly, stiffness (i.e., the cardboard's resistance to bending) depends more on the fiber structure and processing technology. At the same grammage, cardboard made from long-fiber wood pulp, high-density pressed, or specially coated materials often has higher stiffness. This "lightweight yet strong" characteristic is ideal for telescopic boxes—it maintains the straightness of the box walls and structural stability without significantly increasing thickness. Especially at the four corners of the box and the edges of the tracks, high stiffness effectively prevents the accumulation of small deformations caused by repeated pushing and pulling, avoiding problems such as "loosening with use" or "localized warping."

More importantly, the cardboard parameters for the inner and outer boxes need to be matched differently. Typically, the outer box, acting as a fixed frame, requires higher stiffness to maintain overall geometric accuracy; while the inner box (drawer section) can be slightly optimized while ensuring rigidity to reduce sliding resistance. For example, the outer box uses high-stiffness grey board, while the inner box uses slightly lighter but smooth white cardboard, supplemented by precision die-cutting and creasing processes, ensuring both stability and smoothness when they fit together. This "rigid outside, flexible inside" combination strategy is the core of achieving a smooth user experience.

Furthermore, environmental adaptability cannot be ignored. Paper is hygroscopic and may temporarily soften in humid environments, affecting stiffness. Therefore, high-quality telescopic boxes often have a moisture-proof coating on the cardboard surface or use composite structures (such as paper-plastic combinations) to improve environmental stability while maintaining environmental friendliness. At the same time, the selection and application method of the glue used for gluing the box must be carefully controlled to avoid excessive glue layer leading to localized hardening or deformation.

Finally, manufacturing precision is the guarantee of performance. Even with proper material selection, deviations in die-cutting dimensions, inconsistent creasing depth, or inaccurate gluing alignment can still result in difficulty in sliding. Therefore, from die-cutting design to production line calibration, every process must be controlled to a "micron-level" standard to ensure that thousands of boxes have a consistent sliding feel.

In short, the smoothness and durability of the telescopic box are not accidental, but rather the culmination of materials science and craftsmanship aesthetics. Through a precise balance of weight and stiffness, the designers have allowed a seemingly ordinary piece of cardboard to express a harmony of strength and softness within a small space—both as stable as a rock and as fluid as water. This is the silent language of high-end packaging: conveying quality through details and interpreting value through experience.

First, the weight determines the basic thickness and strength reserve of the cardboard. High-weight cardboard is typically thicker, providing stronger resistance to compression and bending, suitable for carrying heavier contents or for applications requiring long-term use. However, in telescopic boxes, simply pursuing high grammage is not a good strategy—excessively thick cardboard increases friction between the inner and outer boxes, making pushing and pulling difficult, and even causing jamming due to accumulated tolerances. Therefore, designers need to select an appropriate grammage range based on the product's weight, usage frequency, and structural dimensions, ensuring the box doesn't deform under stress while allowing sufficient clearance for sliding.

Secondly, stiffness (i.e., the cardboard's resistance to bending) depends more on the fiber structure and processing technology. At the same grammage, cardboard made from long-fiber wood pulp, high-density pressed, or specially coated materials often has higher stiffness. This "lightweight yet strong" characteristic is ideal for telescopic boxes—it maintains the straightness of the box walls and structural stability without significantly increasing thickness. Especially at the four corners of the box and the edges of the tracks, high stiffness effectively prevents the accumulation of small deformations caused by repeated pushing and pulling, avoiding problems such as "loosening with use" or "localized warping."

More importantly, the cardboard parameters for the inner and outer boxes need to be matched differently. Typically, the outer box, acting as a fixed frame, requires higher stiffness to maintain overall geometric accuracy; while the inner box (drawer section) can be slightly optimized while ensuring rigidity to reduce sliding resistance. For example, the outer box uses high-stiffness grey board, while the inner box uses slightly lighter but smooth white cardboard, supplemented by precision die-cutting and creasing processes, ensuring both stability and smoothness when they fit together. This "rigid outside, flexible inside" combination strategy is the core of achieving a smooth user experience.

Furthermore, environmental adaptability cannot be ignored. Paper is hygroscopic and may temporarily soften in humid environments, affecting stiffness. Therefore, high-quality telescopic boxes often have a moisture-proof coating on the cardboard surface or use composite structures (such as paper-plastic combinations) to improve environmental stability while maintaining environmental friendliness. At the same time, the selection and application method of the glue used for gluing the box must be carefully controlled to avoid excessive glue layer leading to localized hardening or deformation.

Finally, manufacturing precision is the guarantee of performance. Even with proper material selection, deviations in die-cutting dimensions, inconsistent creasing depth, or inaccurate gluing alignment can still result in difficulty in sliding. Therefore, from die-cutting design to production line calibration, every process must be controlled to a "micron-level" standard to ensure that thousands of boxes have a consistent sliding feel.

In short, the smoothness and durability of the telescopic box are not accidental, but rather the culmination of materials science and craftsmanship aesthetics. Through a precise balance of weight and stiffness, the designers have allowed a seemingly ordinary piece of cardboard to express a harmony of strength and softness within a small space—both as stable as a rock and as fluid as water. This is the silent language of high-end packaging: conveying quality through details and interpreting value through experience.