How can the surface treatment of boutique special-shaped boxes enhance their moisture-proof and wear-resistant properties?

Release Time : 2025-12-12

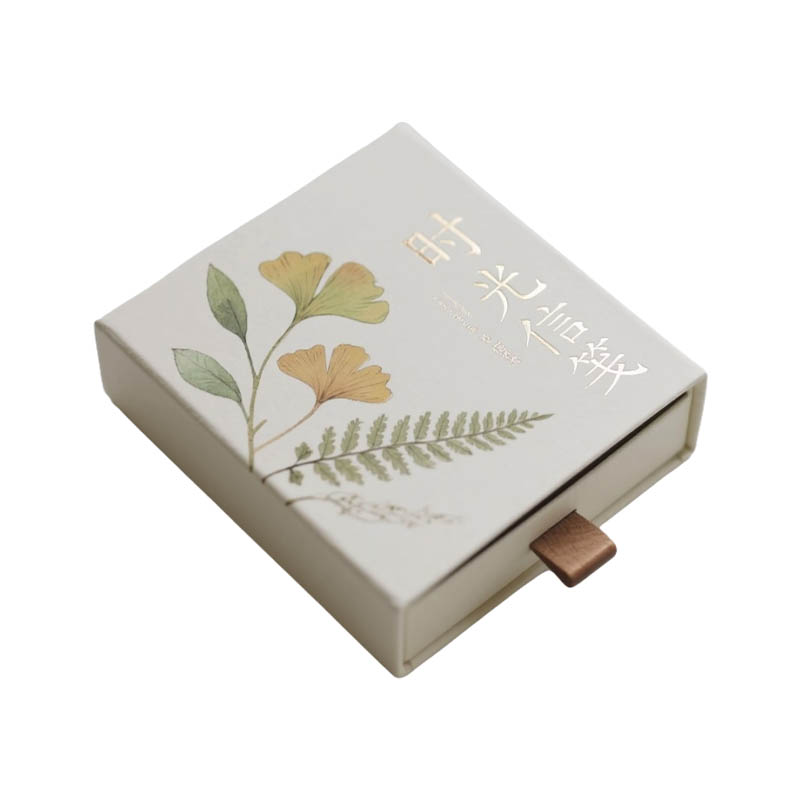

Surface treatment of boutique special-shaped boxes is crucial for enhancing their moisture resistance and abrasion resistance, requiring a multi-dimensional synergy of material selection, process optimization, and functional coatings. Due to their complex structure and varied edges, the surface treatment of boutique special-shaped boxes must balance uniformity and adaptability, forming a continuous protective layer while avoiding treatment blind spots caused by shape differences. This places higher demands on process precision and material performance.

Enhanced moisture resistance primarily relies on the pretreatment of the substrate and the combined application of protective coatings. The substrate for these boxes is typically high-density kraft paper or composite paperboard, with a dense fiber structure and low water absorption, laying the foundation for moisture resistance. During the surface treatment stage, a water-based barrier coating can be applied first. This coating, based on acrylic resin or polyvinyl alcohol, is uniformly applied to the box surface using roller coating or spraying processes, forming a dense molecular barrier that effectively prevents moisture penetration. For scenarios with higher moisture resistance requirements, an aluminum foil composite layer can be superimposed on the barrier coating. The metallic properties of aluminum further isolate external humidity while enhancing the box's stiffness and resistance to deformation.

Improving abrasion resistance requires a combination of hardened coatings and surface texture design. Hardened coatings typically use UV-cured paints with highly cross-linked acrylate groups in their molecular structure. Upon UV irradiation, they rapidly cure, forming a transparent protective layer with a hardness of 3H or higher. This coating not only resists daily friction and scratches but can also be further enhanced in surface hardness and abrasion resistance by adding nano-silica or alumina particles through formula adjustments. Furthermore, surface texture design can be achieved through molding processes, such as embossing fine diamond or wavy patterns onto the cardboard box surface. This increases the coefficient of friction to prevent slippage, reduces wear risk by dispersing localized pressure, and gives the cardboard box a unique tactile and visual effect.

Adapting to irregularly shaped structures is a core challenge in surface treatment. Due to the numerous edges, curves, and grooves in boutique special-shaped boxes, traditional flat processing methods often result in coating buildup or incomplete coverage. Therefore, flexible spraying technology is required, using adjustable-angle spray guns and intelligent control systems to ensure uniform coating adhesion on complex surfaces. For deep grooves or corners, a combination of manual touch-up and localized reinforcement techniques can be used. High-viscosity coatings applied with a brush or sponge can be used for fine finishing, avoiding weak areas caused by the limitations of mechanical spraying. Furthermore, protecting die-cut edges is equally crucial. An edge sealant can be applied to the cut edges after die-cutting to prevent edge warping or delamination caused by fiber swelling due to water absorption.

Environmental friendliness is a key consideration in modern surface treatment processes. The widespread use of water-based coatings and UV-cured coatings significantly reduces volatile organic compound (VOC) emissions, aligning with the trend towards green packaging. Water-based barrier coatings use water as a solvent, leaving only trace amounts of additives after drying, making them harmless to the environment and human health. UV-cured coatings achieve rapid curing through photoinitiators, eliminating the need for high-temperature baking and consuming only one-third the energy of traditional thermosetting processes. Simultaneously, some high-end cardboard boxes have begun using bio-based coatings, derived from vegetable oils or starch, which are completely biodegradable, further promoting the sustainability of surface treatment processes.

Functional integration is the future direction of surface treatment. By integrating moisture-proof, wear-resistant, antibacterial, and anti-counterfeiting functions into a single coating system, the process can be simplified and the overall performance of cardboard boxes can be improved. For example, silver ion antibacterial agents can be added to UV-cured coatings to give the cardboard box surface long-term antibacterial capabilities, meeting the hygiene requirements of food and pharmaceutical packaging; or anti-counterfeiting labels can be directly embedded into the coating through nanoprinting technology, which does not affect the appearance and is difficult to counterfeit, enhancing brand protection.

The surface treatment of boutique special-shaped boxes needs to be based on materials science and driven by process innovation. Through the synergistic enhancement of moisture-proof and wear-resistant properties, it can meet the dual needs of high-end packaging for functionality and aesthetics. In the future, with the further development of nanotechnology, smart coatings, and environmentally friendly materials, surface treatment processes will evolve towards greater efficiency, intelligence, and greener practices, providing stronger support for expanding the application scenarios of boutique special-shaped boxes.