How can we design cushioning structures for boutique special-shaped boxes that are more effective for packaging fragile items?

Release Time : 2026-01-09

In boutique special-shaped boxes for fragile goods packaging, the cushioning structure design must balance protective performance and aesthetic presentation. It needs to reduce impact force through a reasonable distribution of forces while conveying brand value through a unique shape. The core lies in building a multi-layered protective system through material selection, structural innovation, and process optimization, while maintaining the lightweight and refined feel of the box, avoiding excessive packaging that negatively impacts the user experience.

Material selection is the foundation of the cushioning structure. While traditional corrugated cardboard is inexpensive, its cushioning performance is limited and it easily deforms and fails after repeated impacts. Boutique special-shaped boxes often use high-density honeycomb cardboard or EPE (Expanded Polyethylene) composite materials. The former disperses impact force through its honeycomb structure, while the latter absorbs vibration energy through its closed-cell structure. For high-end fragile goods, air column bags or EVA foam can be embedded locally to further reduce the risk of breakage through air cushioning or elastic deformation. The material surface needs to be treated for moisture resistance to prevent strength loss due to humidity changes and ensure long-term stability in the transportation environment.

Structural innovation must be combined with the shape characteristics of the fragile goods. The advantage of boutique special-shaped boxes lies in their customizable linings to fit the product's contours. A "fitting design" minimizes gaps and prevents shaking and collisions during transport. For example, wave-shaped inner clips can be designed for glassware, using curved surfaces to distribute pressure; layered dividers can be designed for electronic products, separating and protecting fragile components such as screens and bodies. Furthermore, a "floating structure" can be used to fix the product in the center of the box, with buffer space around the edges, allowing impact force to be transmitted to the product through box deformation rather than directly to the product. For irregularly shaped products, such as irregularly shaped ornaments or artworks, 3D modeling is needed to simulate the transport scenario and optimize the distribution of support points for the lining.

A multi-layered protection system is key to improving safety. The outer cardboard box must have sufficient compressive strength, typically using thickened grey board or double corrugated structure to resist stacking pressure; the middle layer is filled with cushioning materials, such as shredded paper, bubble wrap, or foam particles, to absorb vibration energy; the inner layer, where it directly contacts the product, uses soft materials such as velvet, sponge, or silicone pads to prevent scratches. Each layer must be secured with slots or adhesive to prevent shifting during transport and loss of protection. For example, when designing for ceramic vases, the outer layer uses a rigid cardboard box for pressure resistance, the middle layer is filled with EPE pearl cotton, and the inner layer is wrapped with velvet, forming a three-tiered protection of "hard-soft-flexible".

Process optimization enhances the reliability of the cushioning structure. The cutting precision of boutique special-shaped boxes directly affects the fit between the lining and the product, requiring laser cutting or CNC die-cutting technology to ensure smooth, burr-free edges. Folds need to be reinforced with creases to prevent the structure from loosening due to repeated opening and closing. For complex shapes, such as curved inner clips or three-dimensional supports, hot melt adhesive or double-sided tape is used for fixing to ensure a firm connection between components. Furthermore, surface treatments such as lamination, UV printing, or hot stamping not only improve aesthetics but also enhance the box's wear resistance and moisture resistance, extending its lifespan.

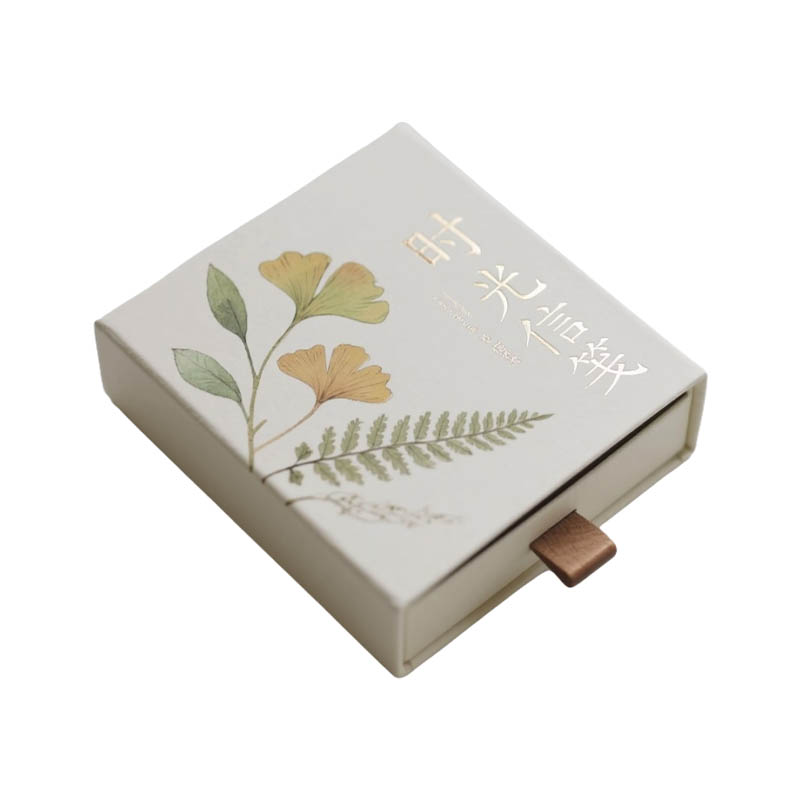

User experience must be integrated throughout the design process. While the cushioning structure prioritizes protection, the opening experience is equally important. Boutique special-shaped boxes often employ "window designs" or "magnetic opening," allowing users to see the product directly while maintaining overall aesthetics through concealed cushioning structures. For example, when designing boxes for jewelry, a rigid cardboard outer layer protects the jewelry, while an inner velvet lining secures it. The product automatically pops out with a magnetic clasp when the box is opened, offering both security and a sense of occasion. Furthermore, the ease of access to the lining must be considered to avoid complex structures that make it difficult for users to remove the product.

Environmental protection and sustainability are crucial considerations in modern packaging. Cushioning materials should prioritize biodegradable or recyclable options, such as paper honeycomb, bio-based EPE, or biodegradable bubble wrap. Structural design should minimize material usage, achieving "lightweight protection" through optimized layout. For instance, a "one-piece lining" design integrates multiple cushioning components into a single structure, reducing splicing processes and material waste. Additionally, the box surface can be printed with eco-friendly logos or printed with soy ink, conveying the brand's social responsibility.

Testing and iteration are the final steps in ensuring the effectiveness of the design. Simulated transportation tests (such as drop tests and vibration tests) are necessary to verify the performance of the cushioning structure. Based on the test results, material thickness, structural shape, or filling methods should be adjusted. For example, if a certain part is found to be easily damaged in a drop, local support can be added or a higher-density material can be used. At the same time, user feedback can be collected to optimize the opening experience or the way the inner lining is placed, making the packaging both safe and practical.